Product & nbsp; Introductions

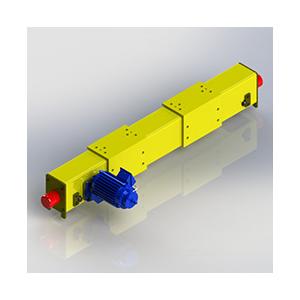

Double-girder crane end beam is modularized by rectangular tube, driven by buffer motor and forged wheels. The NC boring and milling machine is used to complete drilling, reaming, boring and milling processes at one time, effectively ensuring high dimensional accuracy. You only need to correct and weld the main girder and end girder of the crane. Super-high convenience makes the manufacture, installation and maintenance of your crane extremely easy.

.jpg)

< br />

The whole set of end beams includes: wheels, motors, photoelectric limiters, main beam connecting plates, main beam connecting bolts, head plates, natural rubber buffer, etc.

.jpg)

Functional Feature Description

Photoelectric Limiter

The built-in self-adapting photoelectric limiter developed by the company is compact and directly installed in the end beam. It can be directly limited without repeated debugging. The induction range is 0-mdash; 2 meters can be arbitrarily adjusted, replacing the traditional limit switch, greatly improving the beauty of the end beam.

Forged wheels

Wheels adopt combined structure, 45 # steel body blackening heat treatment, bearings adopt heavy-duty sealing structure, safe and wear-resistant, prevent repeated maintenance, greatly improve production efficiency.

Buffer motor

The end beam drive adopts the electromagnetic brake buffer motor produced by the company itself, which has smooth start, sensitive brake and beautiful and compact appearance.

Headboard

The head plate is all stamped by dies and galvanized in various colours, which conforms to the aesthetic view of European customers and is convenient for modular manufacture of end beams.

Buffer

Buffers are made of natural rubber and backed by 3mm galvanized steel sheet. They can withstand repeated heavy loads without damage and protect the end beams.

.jpg) < br />

< br />.jpg)