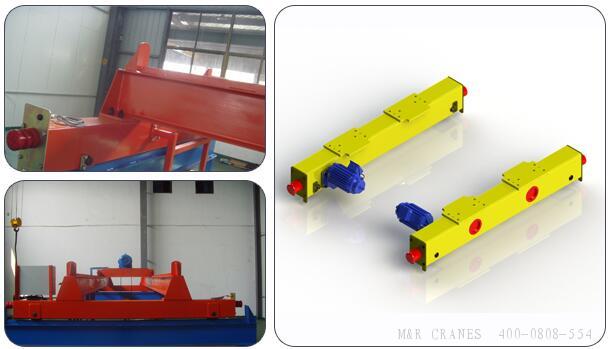

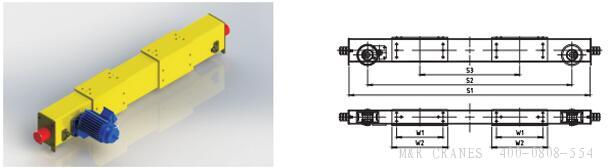

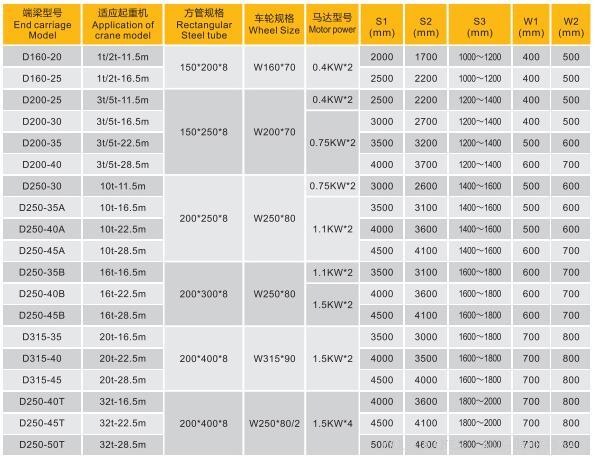

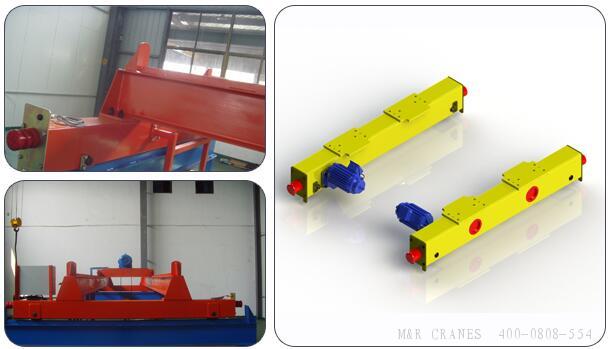

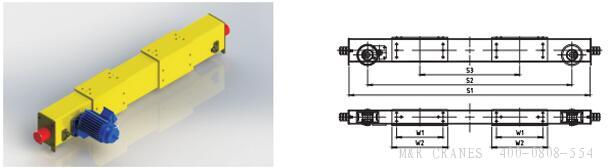

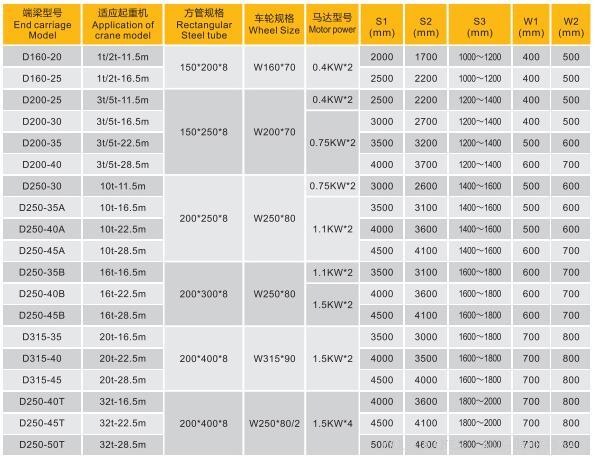

Double-girder crane end beams are manufactured by rectangular pipe modularization, driven by buffer motor, with forged wheels completed by CNC boring and milling machine at one time, which effectively ensures high dimensional accuracy. You only need to correct and weld the main girder and end girder of the crane. Super-high convenience will enable your crane to manufacture/install. / Maintenance is incredibly easy.

< br />

< br />

< br />

The whole set of end beams includes wheel/motor/photoelectric limit device/girder connecting plate/girder connecting bolt/head plate/buffer.

Characteristic Description

Photoelectric Limiter

The built-in self-adaptive photoelectric limiting device developed by the company is compact and directly installed in the end beam. It can be directly limited without repeated debugging. The induction range is 0-2m and can be adjusted arbitrarily. It can replace the original mechanical limiting switch. The beauty of the end beam can be greatly improved.

Forged wheels

< br />

The wheels adopt combined structure, 45 # steel body blackening heat treatment, bearing adopts high quality bearing with heavy-duty sealed structure, which is safe and durable. Repeated replacement and maintenance are completely eliminated, and downtime is reduced. The efficiency has been greatly improved.

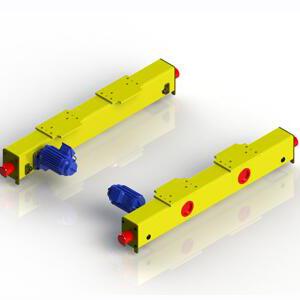

Buffer motor

< br />

The end beam is driven by an electromagnetic brake buffer motor, which has a smooth start, high braking sensitivity and beautiful appearance.

Headboard

< br />

The head plate is stamped and galvanized at one time, which conforms to the aesthetic view of European customers and facilitates the rapid production of end beam die.

Buffer

< br />

Buffers are made of natural rubber and backed by galvanized sheet with a thickness of 3 mm. They can bear repeated heavy impact and protect end beams from damage.

< br />

< br /> < br />

< br /> < br />

< br /> < br />

< br /> < br />

< br /> < br />

< br /> < br />

< br />